DUOTONE: WARP_FIN AND FALCON_FIN D/LAB

Due to high demand, Duotone have decided to launch the WARP_FIN & FALCON_FIN D/LAB to the market one month early and now you can check out these new racing machines on their website now!

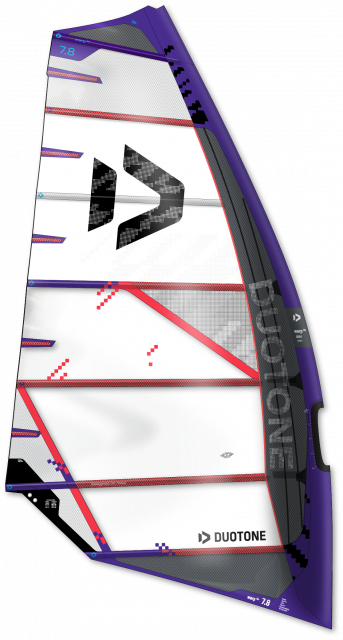

WARP_FIN IN SHORT:

Refined and tuned to allowed you to unleash you potential on the race course! PWA FIN racing will be back in 2024 and we have the ultimate setup for you. As the only brand to have not only more than one, but FOUR riders winning PWA winners finals on fin in 2023, we have continued to be dedicated to the fin slalom discipline and continually creating race winning products.

For 2024 the WARP_FIN has an even wider range than ever before and more explosive acceleration.

PWA Fin Racing is back and we have an unbeatable package for you!

After the redesign in 2022 we have constantly modified and tweaked every single size and can firmly say the changes we made led to the best slalom racing sails we have every made. How do we validate this claim? Well for a start in 2023 we were the only brand to win a PWA Slalom Race with Pierre Mortefon and Jordy Vonk both taking victories against the Foils. Add this to the 8 Slalom World Champions and 20 World Class Podiums in 2022 and the racing stats of these sails speak for themselves. With many high performing junior performances too, not only is the WARP_FIN the best racing sail for our professional World Class Athletes, but also for our highest performing juniors. For all sizes and skill levels, the WARP_FIN is the best fin-slalom racing sail on the market.

What did we do to make such an incredible sail? Firstly, the WARP_FIN is ready to race right out of the bag. Unlike most other slalom racing sails the WARP_FIN does not need any time-consuming fine tuning. Even with our slalom racing sails our aim it that you just take your sail out of the bag, rig it according to the visual markers, and you can be assured to have the performance than our racing team. In racing, maximum acceleration and control over the material are what count when it comes to standing at the top of the podium. You need ultimate speed and control on the course, but also to be able to sail for many hours in a row to win at the end of the week. The more pronounced High Aspect Ratio design, especially in the larger sizes, with a shortened boom length and a forward-shifted profile, requires less power, is lighter in the hands and offers more control at the upper wind limit. In addition, stiffer tube battens stabilize the shape well into the overpowered range and you can easily convert even monster gusts into extra speed.

Overall, the WARP_FIN is more balanced, less exhausting, and even more controllable.

On the other hand, acceleration was also improved to make up ground after the start and jibes. Based on the successful NO COMPROMISE DESIGN concept, the draft position was moved a bit further up, to lift the board which leads to improved planing and explosive acceleration thanks to reduced resistance. The NO COMPROMISE DESIGN also made it possible that the propulsion does not start abruptly and must be “muscled down” but builds up much more gradually and softly than with other power slalom sails! This relieves the pilot, giving them extra power reserves for the entire course and full concentration on the race. There are other positive side effects of the modified profile geometry with a higher draft position: the trim of the board improves, making it easier to fly on the rail and in combination with the unrivalled soft camber rotation the sail jibes even more effortlessly and faster. Over the last 12 months every single size got tweaked to perfection by modifying the luff curve, profile distribution and twist pattern.

As a result all sizes: + have an even more explosive acceleration now + offer an even bigger wind range!

FALCON_FIN D/LAB IN SHORT:

What if you could have it all?

A race winning shape, decades of experience AND an unbeatably stiff, light weight custom construction? The FALCON_FIN D/LAB is a completely new construction – with CUSTOM CNC SANDWICH TECHNOLOGY, it is the first board we have launched with the D/LAB seal of approval, denoting the desire to make the best windsurfing gear possible using the best materials and construction methods on the planet, with no holds barred. It truly is the performance racer’s dream due to the world-class race board designs combined with mind-blowingly light weight, no compromise stiffness and individual layup to make a production slalom board unlike anything else on the market. Not only are all sizes now coming in the new construction but the 90 is also a completely new shape to accompany the 99 & 116 shapes that were successfully introduced this year and are the only fin boards to win a Men’s PWA final in 2023.

Over the last 3 years Dani Aeberli (product manager boards) and Vasin Siritho (implementation + QC manager) have worked out a technology being worthy to qualify for the D/LAB label. Instead of the usual semi-custom technology we are now using a 100% full custom technology. We call this CUSTOM CNC SANDWICH TECHNOLOGY

Even before hitting the water you can already get an idea of what to expect. Simply lift the board and you will be shocked how light it is. Then knock on the hull and you immediately realise how stiff the board is. Compare it with a typical production board and the difference is imminent.

The result on the water is truly mind-blowing. Due to the massively reduced weight (up to 500g) and the incredible additional stiffness, even the unchanged shapes feel like a completely new board. The acceleration is on a totally different level than anything we have produced before. It is a true silver bullet compared to anything else on the market.

And best of all our shapes are still beyond doubt. The PWA World Title winning Falcon_Fin boards are designed for total control in every situation you’re facing on a racecourse. Your focus stays 100% on your speed and your line, rather than your equipment. Pierre Mortefon has already demonstrated that in 2019, when he won the PWA Slalom World title with our rocket ships. 2021 he proved it once again by finishing as PWA Slalom Vice World Champion, and to put the icing on the cake, Jordy Vonk and Jenna Gibson became 2022 IFCA Slalom World Championships in the dedicated, fin-only World Championships.

In 2023 we redeveloped the key sizes 99 & 116 according to our top riders demands for 100% performance on the racecourse. The recessed mast base area keeps the rig connection low for better control, while the cut-out rail design will ensure 100% power and straightforward jibes on the course.

For 2024 now follows the size 90 which will be a key size in next year’s PWA fin racing. It’s based on the 99 design which everyone just calls the “magic board”.

FALCON_FIN D/LAB – we are very convinced that the combination of the most competitive shapes and our brand new CUSTOM CNC SANDWICH TECHNOLOGY will be the board which leads you to the podium – at your local spot or on any fin racing competition. WHAT IF? You could have it all? A race winning shape, decades of experience AND an unbeatably stiff, light weight custom construction?

CUSTOM CNC SANDWICH TECHNOLOGY

The CUSTOM CNC SANDWICH TECHNOLOGY is a full custom technology which is one hundred percent identical to high-end custom made boards.

Instead of using a mould to bring the EPS foam core into its final shape each EPS block gets CNC milled. This ensures maximum precision and saves weight. Same as with high-end custom board makers the major advantage lays in the processing. We call this SINGLE PROCESS TECHNOLOGY and it is the key to our industry-leading weight-strength ratio. Instead of combining working steps to save time and money every single step follows its individual process.

So, for example instead of joining the PVC sandwich with the EPS core in a single shot we vacuum-bag the top and bottom PVC shields with the EPS core separately. Also, instead of using standard 3mm PVC elements for the entire board we use thicker and thinner PVC plates as well according to the stress areas which makes the board lighter yet stronger.

For all D/LAB boards we use our most sophisticated layup which consists of more than 60 individual parts and components (nearly 20% more parts than used for our SLS PREMIUM SANDWICH CONSTRUCTION). On top we are using the most high-end composite materials available to-date. All carbon fibres used are a mix of high strength and high modulus carbon qualities depending on the individual requirements of each board section. Our high modulus carbon used can also be found on high-end products like aircraft’s, Formula One cars or our Platinum SLS masts, booms and extensions. Innegra is a high modulus Propylene with unbeatable tensile and ding resistance.

We use our exclusive high performance S-glass fiber with an extra high silica content which offers much higher tensile strength as well as about 10-20% greater stiffness. And finally we are using our exclusive DUOTONE SENTEX® resin impregnated with silicon nano-spheres which helps us to reduce the weight even further without sacrificing durability. Instead of using a similar layup on all boards we use a DISCIPLINE SPECIFIC FLEX CONSTRUCTION for all our D/LAB boards since demands on the different disciplines (wave, freestyle, freeride, racing) and conditions vary quite a lot. Racing boards are made to offer maximum performance (instant acceleration and V-max). Therefore, these boards need be as stiff as possible. To achieve this no compromise stiffness we use a super high carbon content on all FALCON D/LAB layups. On wave boards though a certain “give” is essential since these boards are very short and might become too stiff thus uncontrollable using a full carbon layup. Therefore the GRIP D/LAB boards come with a higher Innegra + S-glass content.

These high-tech composites have a much higher tensile strength avoiding breakages after high landings. To still achieve an outstanding“spring-back“ characteristics which makes the board more reactive and has a tremendous effect on the acceleration we use unidirectional Carbon reinforcements in longitudinal direction. Last but not least even every single board size has an individual layup. That’s the final stage of individualisation in construction.

The result speaks for itself since the D/LAB boards are up to 500 grams lighter than our SLS boards and up to a full kilo lighter than other serial production boards. And it’s the first time that a production board can compete even with the lightest custom boards out there.

Yet all of this is achieved without any sacrifice in durability since we always follow our core motto LIGHT DONE RIGHT!

DUOTONE Windsurfing ᐅ Welcome to True Windsurfing. (duotonesports.com)